Product

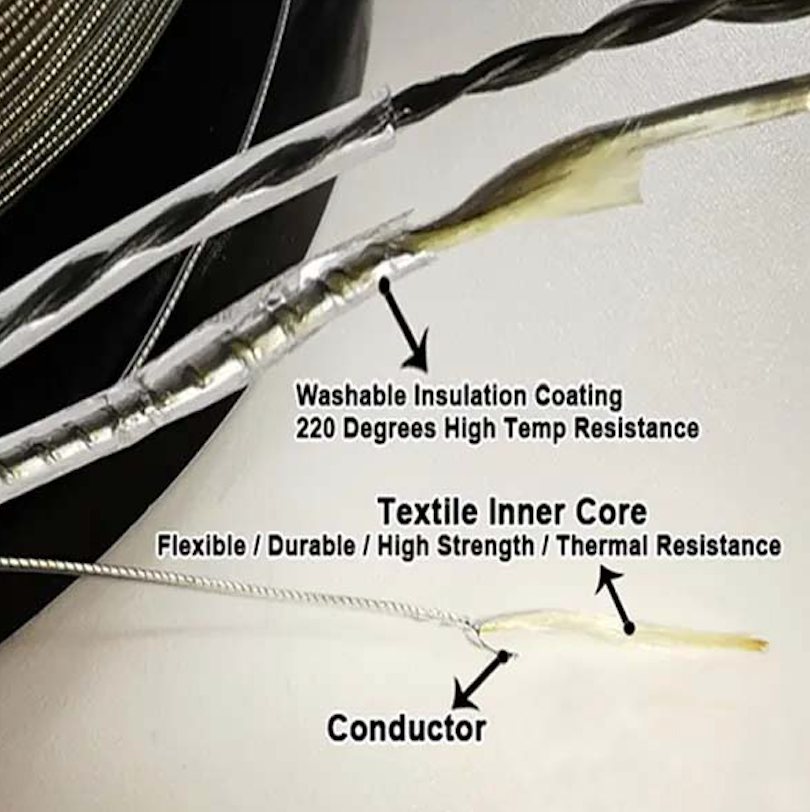

Stainless simbi bundle faibha kana textile inner core conductive waya yemachira anopisa

Product Description

1-Stainless simbi faibha based bundle uko dhayamita yega yega faibha iri 12µ kana 14µ. Huwandu hwefibers hunowanzo kubva kumativi mazana maviri kusvika pamusoro pe1500 filaments. Izvi zvinokupa kusimba zvinova 'zvakanakisa mukirasi'. Nekuda kwemafibhi akanaka anoshandiswa, tambo idzi dzichiri dzakatetepa muhupamhi hwese uye nekudaro dzinochinjika mukugadzirisa.

2-Isu tinovhara huwandu hwakakura hwekudzikisira yakawedzera tambo waya uye tambo diki dzine akasimba uye anochinjika hunhu, akakosha edu ane machira emukati epakati tambo tambo dzinogona kugutsa kuramba pamita yaunoda uye inokupa iwe kuchinjika mukugadzira asi zvichiri kupa zvirinani. flex-hupenyu kupfuura akajairwa Cu-cables. Zvichienderana nekunze kwakaputirwa alloy iyo inogona kuiswa tini, mhangura, sirivheri alloy nezvimwe, tinogona kugadzira conductive inopikisa kunyange yakaderera kupfuura 1 ohm/m tambo diki nemhando imwe uye yakasungwa zvinoenderana nezvinodiwa nevatengi.

Textile yemukati core micro cables zvakanakira

Bending Resistance

Nekuda kwechimiro uye kusanganiswa kwezvinhu, waya ine yakanakisa kubhenda kuramba.

Kuchinja-chinja

Iwo ma micro tambo anoshandisa yakaonda simbi foil se conductor, iyo inoziva super kuchinjika.

Ultra-Yakanaka

Mushure me extrusion yedu diki tambo yakaonda inogona kusvika 0.35mm.

High Tensile Simba

Isu tinoshandisa Aramid / Liquid Crystal Polymer fiber uye self engineer high tech fibers.

High Temp. Resistance

Isu tinoshandisa aramid kana stanless simbi faibha bundle mafilaments efibers, yakakwira temp inoshingirira kubva pa230 madhigirii kusvika 580 madhigirii esarudzo yako.

Kupedzisa & kupfekedza

Munyika yako, pane kunyanya kudiwa kwega-lacquering yemafilaments kana yeakazara extrusion coating pamusoro petambo yakazara. Tinogonawo kuita izvozvo, yedu extrusion zviri mukati zvinosanganisira FEP,PFA,PTFE,TPU etc.

INSUlation JACKET DESCRIPTION

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205° C | 255° C | 250°C |

| Cenderera Kushanda Temperature | 165° C | 205° C | 225° C |

Stainless Simbi Fiber Masumbu

Textile Inner Core Micro Cable Constructions

Yakavakirwa Embroided Heating Element

Stainless simbi inounganidza zvakasiyana siyana zvekupikisa zvereferensi yako.

| Diameters (um) | Filaments | Simba (cN) | Huremu (g/m) | Elongation (%) | Conductivity (Ohm/ m) |

| 8 | 1000F x 1 | 69 | 0.420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0.850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0.540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0.780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0.950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Textile inner core conductive wire dzakasiyana siyana dzekupikisa

| Outer Conductor | Textile Inner Core | Diameter mm | Conductivity ≤Ω/m |

| Mhangura 0.08mm | 250D Poyester | 0.20±0.02 | 6.50 |

| Mhangura 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |

| Mhangura 0.05mm | 50D Kuraray | 0.10±0.02 | 12.30 |

| Mhangura 0.1mm | 200D Dinima | 0.22±0.02 | 4.00 |

| Mhangura 0.1mm | 250D Polyester | 1*2/0.28 | 2.00 |

| Mhangura 0.1mm | 200D Kevlar | 0.22±0.02 | 4.00 |

| Mhangura 0.05mm | 50D Polyester | 1*2/0.13 | 8.50 |

| Mhangura 0.05mm | 70D Polyester | 0.11±0.02 | 12.50 |

| Mhangura 0.55mm | 70D Polyester | 0.12±0.02 | 12.30 |

| Mhangura 0.10mm | Donje 42S/2 | 0.27±0.03 | 4.20 |

| Mhangura 0.09mm | 150D Polyester | 0.19±0.02 | 5.50 |

| Mhangura 0.06mm | 150D Polyester | 0.19±0.02 | 12.50 |

| Tin Mhangura 0.085mm | 100D Kuraray | 0.17±0.02 | 5.00 |

| Tin Mhangura 0.08mm | 130D Kevlar | 0.17±0.02 | 6.60 |

| Tin Mhangura 0.06mm | 130D Kevlar | 0.16±0.02 | 12.50 |

| Tin Mhangura 0.10mm | 250D Polyester | 0.23±0.02 | 4.00 |

| Tin Mhangura 0.06mm | 150D Polyester | 0.16±0.02 | 11.6 |

| Tin Mhangura 0.085mm | 200D Kevlar | 0.19±0.02 | 5.00 |

| Tin Mhangura 0.085mm | 150D Polyester | 0.19±0.02 | 6.00 |

| Sirivha Mhangura 0.10mm | 250D Polyester | 0.23±0.02 | 3.90 |